1

/

of

1

CaliDTF

Kothari Print Pro RIP for Direct to Film Printing (DTF)

Kothari Print Pro RIP for Direct to Film Printing (DTF)

Regular price

$849.95 USD

Regular price

Sale price

$849.95 USD

Unit price

/

per

Couldn't load pickup availability

Kothari RIP for Direct to Film printing is hands down the most powerful, high quality production RIP in the industry! Blow away the competition with stunning, highly detailed graphics - this RIP works equally well on photo-realistic images AND vibrant illustrations.

While easy to learn and use, Kothari RIP is incredibly powerful and allows the end user full control over the final output.

Technical Specification.

- Requires a PC based on Intel core i3 running at 2.3 GHz or better processor. RAM 2GB or more.

- Operating system: Microsoft windows 7 or later.

- Hard Disk: Hard drive requirement varies based on your usage requirement. We recommend 500 GB or more fast SATA/ SSD (SSD preferred), with at least 20GB of free space.

- Monitor: 24 bit color or better, with minimum resolution of 1366x768 pixels (recommended 1920x1080 pixels).

- One USB port for software dongle.

Highlights.

-

Color Control.

- Color managed workflow. Open images in any color space (RGB, CMYK, Lab) for printing. Embedded color profiles in images are read and recognized for proper interpretation of the intent of the designer.

- Color tools like Color Book, Direct Color Editing (DCE) and Direct Channel Firing (DCF) for managing Spot colors in the images.

- Color profiling tools. With easy to use wizard based interface, these tools are best in the class , specially designed to work with white ink to produce high quality color profiles tuned to optimize use of white ink.

-

White Ink handling.

- White underbase generation. Automatic generation of white underbase based on the media color type, resulting in optimized usage of white ink based on media color without compromising on color gamut. The software recognizes and uses transparency information in the images during the underbase generation.

- White highlight.

- Underbase choke.

- Ink cost calculator. Compute the print cost for each print based on the ink consumption. This allows you to know your cost of printing before you commit for an order.

- Job tracking and accounting. Track usage of the printer with respect to jobs printed, their print settings, number of copies and ink consumed. MIS can be generated for Job accounting purposes. Multiple printers can be tracked and programmed for automatic reporting in combination with our KoJac.

- XML based, barcode controlled workflow for Job automation. Designed to bring efficiency at the shop floor and reduce chances of errors in production, this is a must have tool no matter what your size of business is. If you are accepting orders through the web, then you can automate your production process by directly generating XML tickets and placing them in the queue and tagging the garments with corresponding barcodes. Alternatively, if you don't use the web then also, you can generate XML tickets using our Job panel for all the jobs. This panel is also capable of pulling data from a database. The RIP software takes instruction from the XML ticket and knows from there, how to process the incoming Job. Also, the moving XML Job ticket in your network allows your IT systems to keep track of the progress made on a particular Job as it moves through various stages of its life cycle - from order point to printing until shipment. As a business owner, it helps you plan your production and supervision more efficiently, reducing chances of mistakes. This frees you from production blues and let you focus on your task of managing your business!

-

Platen organizer/ Layout template.

- Production optimization. If you have a printer with larger print area, it is more efficient to print multiple garments at the same time. These multiple garments need not be of the same garment color and hence may have different requirements for printing. The software allows the user to organize the layout of print area by placing multiple platens on it and giving each platen a name. The platen placement definition is saved as a template file for reuse along with multiple print settings for each possible garment color type. At the time of actual printing the user can select which platen will have what type of garment color to print. Accordingly based on the garment color, the software will use the appropriate printer settings from the predefined settings.

- Flexible image composing. On the same platen you can place multiple images with transparent background to compose. This is very useful when you wish to use the same image but with different message text on multiple garments. The images on the same platen can be in different color spaces (RGB, CMYK, Lab).

-

Output Quality.

- Bi-cubic expansion of images for excellent details and resolution enhancement.

- Advanced dithering with variable dot control for exceptional smoothness and print quality.

-

Reliability and ease of use.

- Memory management for handling almost unlimited size of image data without significant impact on the performance.

- Stable platform that rarely crashes, allowing you to focus on your Job than worrying for the next event !

- Intuitive user interface.

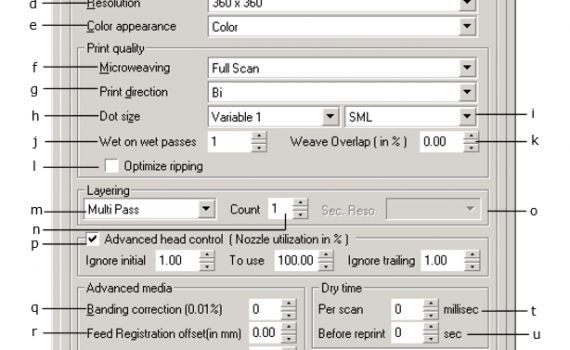

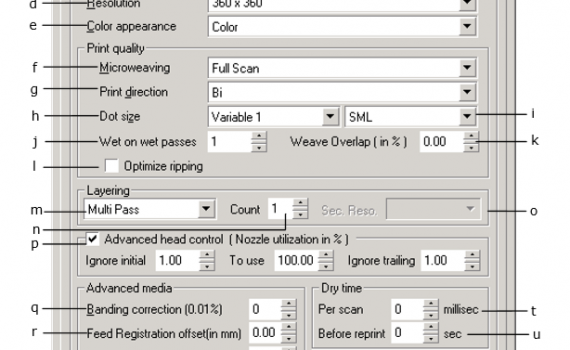

- Hide print settings complexities behind the user defined definitions, like templates and print environments. These can be shared among various print stations using printer of same type and recalled easily from a drop down list.

- Installation of new print modes and taking backup of existing print modes is easy. This allows to keep backup of various customization done for printing, in due course of time.

- Handle more than one printer with the same software.

- Port Manager. Define ports and associate them with the name of the Printer as identified on the shop floor for easy recall.

- Print Queue Manager. Load, RIP, Print and Manage Jobs in the same queue going to various printers. Job priorities can be changed by simply moving them up and down in the list. Store RIPPED jobs on the disk for future recall.

- One pass printing is supported with multiple ink layers (more than one) printed in the same pass based on the order of printing. These layers can be of different resolution and head nozzles are utilized accordingly to optimize the print speeds. This feature is available only for printers, where Print Pro's custom drivers can control the printhead nozzles directly.

DOWNLOAD DOCUMENTATION: http://www.dtgprintsolutions.com/kothari-basic-doc...

NOTE: You must be logged in to DTG Print Solutions to download product documentation.

Share